Hyderabad Unit

Hyderabad Plant is equipped with highly integrated and flexible manufacturing facilities to produce a wide variety of special metals and alloys in various mill forms such as forged bars/ flats, Rings; near net shapes and closed die forgings, hot rolled bars/ sheets, cold rolled sheets, strips and foils; wires, castings, tubes and fasteners.

MIDHANI has a unique combination of advanced melting and refining furnaces necessary for melting superalloys, Titanium, special steels etc. to standards required for the industries. MIDHANI produces alloys with close compositional control, metallurgical cleanliness and homogeneity with the help of an impressive array of melting and refining furnaces.

Special steels and Superalloys Melting

- 5T Arc Furnace(EAF) & 20T EAF/LF/VD

- 1.35T/2.2T Air Induction Melting Furnace(AIM)

- 5T Vacuum Induction Refining Furnace(VIR)

- 50kg, 600kg, 2.5T & 6.5T, 8T Vacum Induction Melting Furnaces(VIM)

- 6.5T (Titanium) / 10T (Steel) Vacuum Arc Re-melting Furnace(VAR)

- 10T/20T Electroslag Refining Furnaces(ESR)

Titanium Melting

- MIDHANI has Vacuum Arc Remelting furnace for the production of Titanium ingots upto 6.5 T. For electrode preparation, a 3000 T capacity Compacting press and a Plasma arc welding unit are available.

- Electron beam melting(EBM)

- Vacuum Arc Skull Melting

Forging facility at MlDHANI includes a 1500 T, 6000T hydraulic forge presses and Ring rolling mill. Two rail bound manipulators fully integrated with programmable press functioning ensures close control of forging parameters for most of the alloys, particularly those required for aircraft industry. The forge shop houses a number of LPG fired re-heating furnaces with close atmospheric control ensuring low sulphur pickup and providing superior surface quality.

- 6000T (60MN) forge press

- 1500T (15MN) forge press

- Ring rolling

The heat treatment is by far the most important stage in the manufacture of special metals and alloys, since the end product quality and Properties are depends on evolution of microstructure. Heat treatment operations have to ensure close control of temperature and atmosphere

- PLC controlled LPG fired and Electric heated Bogie Furnaces for Heat Treatment of jobs of various sizes and forms.

- Heat treatment operating temperatures range from 5000C to 11500C.

- Uniform temperature control within ± 5oC to ±100C with constant air circulation is the furnaces.

- Quenching/cooling facilities (Oil, Water, forced Air & Sub Zero)

- Furnaces are calibrated (TUS) and meet AMS2750F accuracy requirements.

- Cryogenic treatment of metals up to -1930C.(minus 1930C).

- A high vacuum furnace is used for annealing of special metals & alloys.

A. SHEET MILL

I.SHEET ROUGHING MILL

1. MAKE: HEC-DEMAG

2. 2HI NON REVERSING,

3. 650DIA ROLL, 1150 MM WIDTH

4. I/P –100MM (max) , O/P–10MM THICK MIN,

5. 80KG MAX WEIGHT

II. SHEET FINISHING MILL

1. MAKE: HEC-DEMAG

2. 2HI NON REVERSING,

3. 650DIA ROLL , 1150 MM WIDTH,

4. I/P–12MM (max) , O/P–5MM THICK MIN , 100KG MAX WEIGHT

B. STRIP MILL

1. MAKE: HEC-DEMAG

2. 3HI SINGLE STAND,

3. 600DIA ROLL , 250-350 MM WIDTH,

4. I/P–55–70MM THK , O/P–5 MM THICK

5. 100KG MAX WEIGHT

C. BAR MILL & WIRE ROD MILL

I.BAR MILL

1. 3HI 3 STAND,

2. 480 DIA ROLL,

3. I/P-100MM/110DIAMM, O/P-30TO75MM DIA,

4. 85KG MAX WEIGHT

II.WIRE /ROD MILL

1. MAKE: MECON-WEAN

2. 3HI 3 STAND,2HI 4 STAND,

3. I/P-45MM,O/P-9 TO 28MM DIA,

4. 16 TO 20 KGS MAX WEIGHT

D. ANNEALING FURNACE

I.ROLLER HEARTH FURNACE

1. (MAKE:DREVER,UK) MAXIMUM TEMP : 1180⁰C

II.BATCH ROLLER HEARTH FURNACE

1. (MAKE:SHOIE,PUNA) MAXIMUM TEMP : 1050 ⁰C

III.FIXED HEARTH FURNACES (8NO’S)

1. 1280 ⁰C MAX,1500KG LOAD

E. ANXILIARY FACILITIES

1. ROLLER LEVELLER (GERMAN MAKE)

CAPACITY:2-7MM THICK, 0.5 TO 2MM THICK

2. STRETCHER LEVELLER (MAKE:BIGWOOD)

UPTO 7MM THICK,1100 WIDE 3000MM LONG,400T

3. PLASMA CUTTING MACHINE (MAKE: KALI, MUMBAI)

UP TO 40 TO 70MM THICK CUTTING, 300-400 AMPS

4. WATER JET CUTTING MACHINE (MAKE:NANOJET,DELHI) UPTO 70MM THICK,1000MM WIDTH

The super alloys, Titanium alloys and many high & ultra high strength steels’ require specialized facilities for cold deformation in to thin gauges. The rolling parameters for these diversed alloys widely vary. Therefore, the cold rolling mills have been carefully designed to ensure precision rolling.

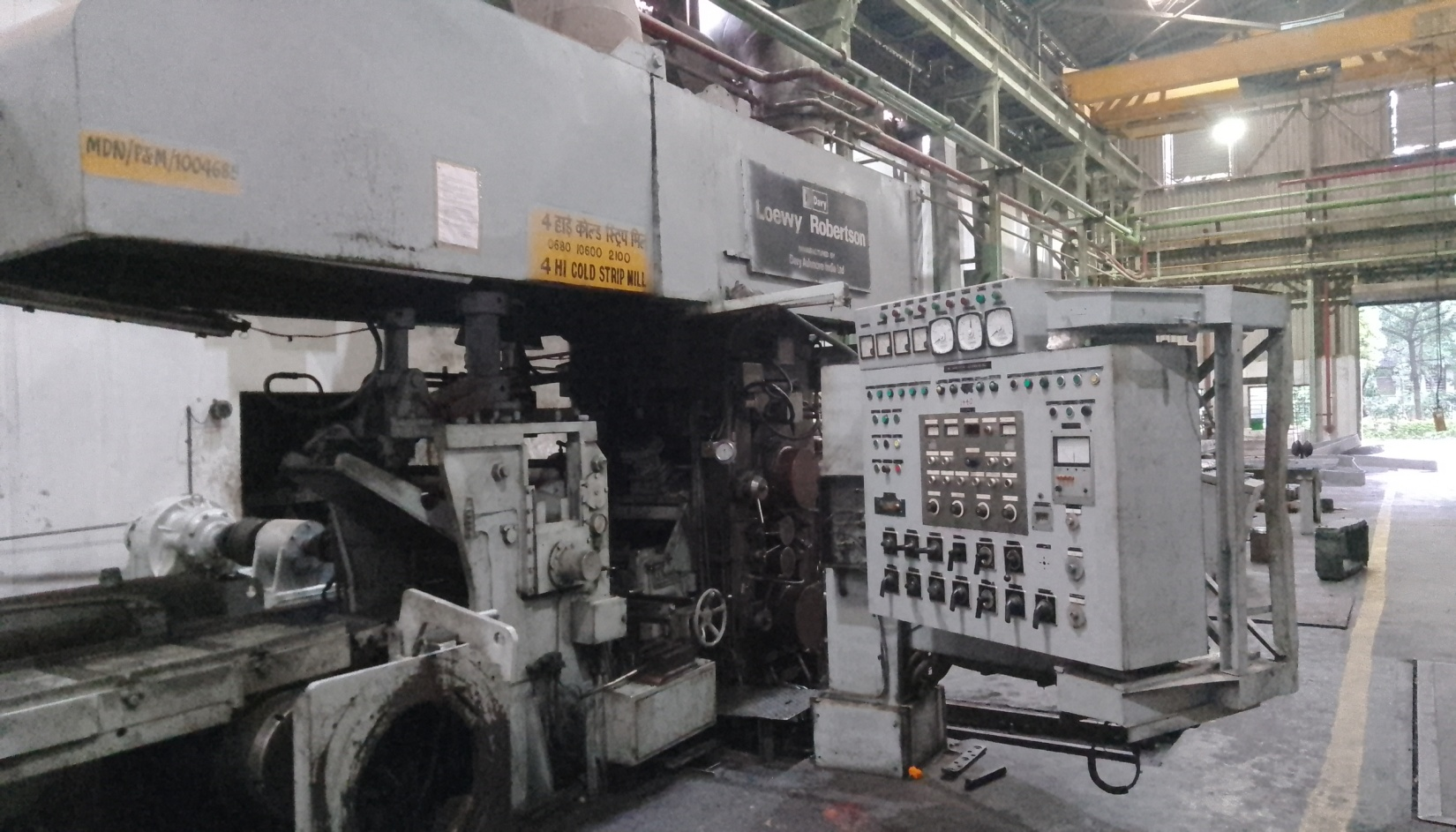

- 4-hi strip mill

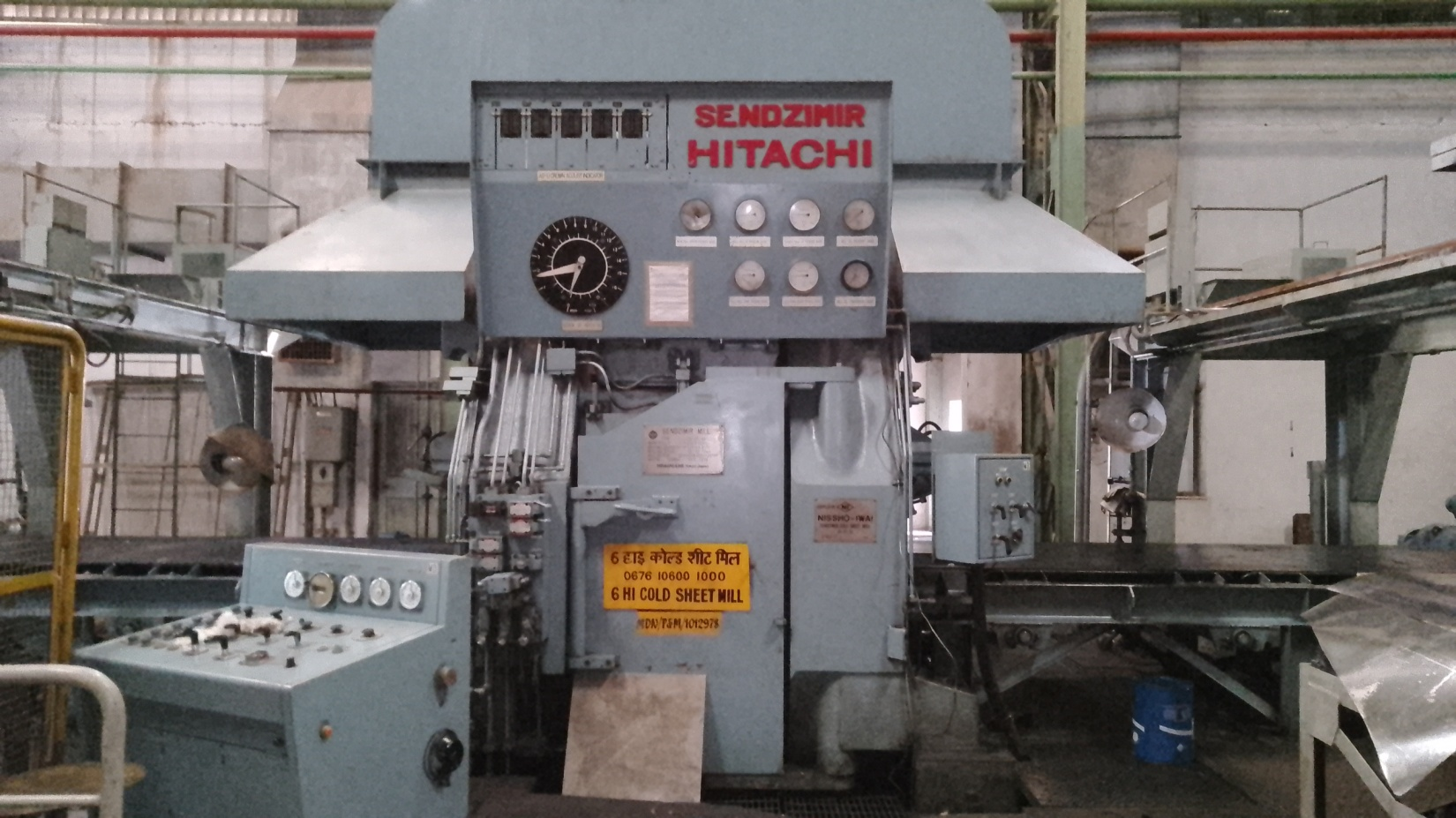

- 6-hi sheet mill

- 12-hi strip mill

- 20-hi foil mill

- Continuous annealing line

- Bell annealing furnaces

- Finishing lines for slitting and strip grinding

Product & size range:

A. Product & size range:

Sheet form: 0.50mm to 7.0mm thick x 500-1100mm width x 500-3000mm length

Strip form (cut to length): 0.50mm to 5.0mm thick x 80-250mm width x 500-3000mm length

Coil form: 0.10mm to 4.0 to mm thick x 80-250mm width(4.0mm to .50mm), 10-250mm width(0.50mm to 0.10mm) x coil

B. Product supply condition:

Cold rolled, cold rolled-annealed*

Cold rolled-annealed & pickled, cold rolled & ground, cold rolled & vacuum annealed**

*strips product

**sheet products

C. Grades:

Super alloys – (nickel, cobalt& iron- base alloy)

Eg. C103, superco605, sni718, sni625, sn80a, ae435, sni 75, sni 325, c276, superfer52, sni 263, ae 868, ae962w, sni 617, ae696)

Heating elements :- superheat 80/60/45/37/30

Titanium alloys – (grade i, ii & iii, bt14, ot 4-1, specialised in ti-31(6al-4v) &titan 44(beta alloy))

Stainless steels – (austenite-12x18h10t, mdn321, mdn 316ti, mdn 316l, mdn 304,304l, 304ln, mdn 312m) (semi-austenitic-mdn 177) (martenisitic-mdn 420&420mo, mdn431)

Special steels – (15-5 ph, 17-4ph, 13-8 mo ph, 11-10ph, 12-10ph, mdn 15-5t, mdn 465, spring alloy, sta59&60)

Low alloy steels – (15cdv6, 30khgsa, 60c2a, vp30, 25cd4s)

Maraging steels – (mdn 250, mdn 350)

Magnetic alloys – (softcomag49a, softmag48b&c, softmagm78a, b&c, softmag 30, 40&76, soft iron)

I. Cold rolling mill facilities:

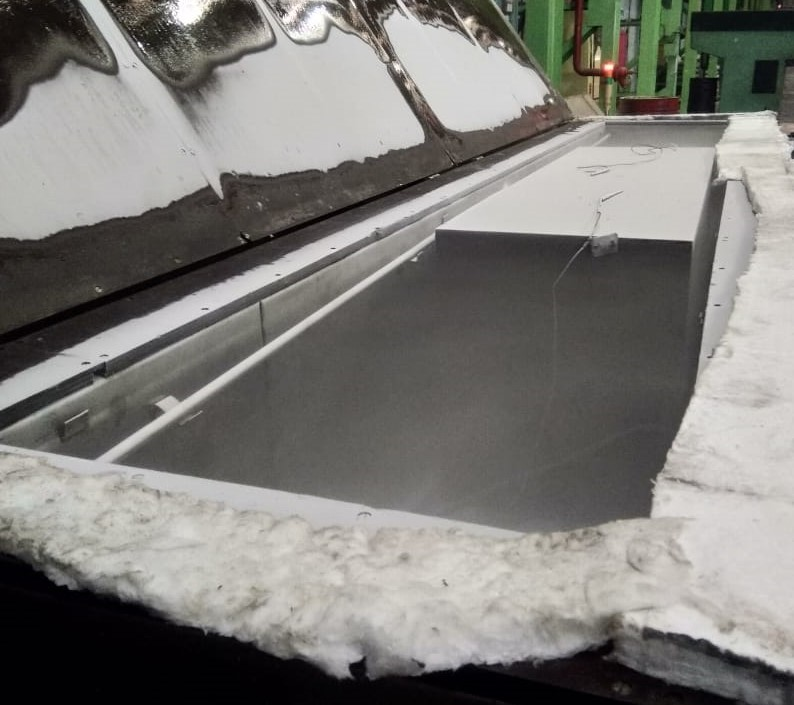

1.6hi-sheet mill: thickness 0.50mm to 7.0mm

width: 500mm to 1100mm

length: 500mm to 3000mm

2.4hi-strip mill: thickness 2.0mm to 4.0mm

width: 80mm to 250mm

cut to length: 500mm to 3000mm

coil form: 1000 od/max 500kg wt.

3.12hi-strip mill: thickness 2.0mm to 0.10mm (100 microns)

width: 80mm to 230mm

cut to length: 500mm to 3000mm upto 0.50 mm

coil form: 1000 od/max 500kg wt. (0.50mm and below)

II. Annealing facilities:

1. Bell annealing: Temperature: 1000 °c

Atmosphere: hydrogen/argon

Furnace capacity: 1-1.5ton.

Coil thickness: 6.0mm to 1.70mm

2. Continous annealing: Temperature: 1100 °c,

Atmosphere: hydrogen

Coil thickness: 1.70mm to 0.20mm

3. Vacuum annealing: Temperature: 1250 °c,

Atmosphere: furnace heating/cooling

Dimensions/capacity: 700 widths x 1200 length x 800 heights/1000kg max.

4. Finishing lines: smap line & stanat line (edge slitting & trimming)

rls (levelling & cut to length)

strips grinding & polishing line (for coil)

sheet polishing machine (sheet product)

The plant is equipped with wire drawing machines, annealing lines, polishing, straightening and cutting machines to draw wires upto a minimum of 0.02dia.

- Bull Block Machines

- Multi head Dry Drawing Machine Wet Drawing Machines

- Automatic Wire Straightening and Cut to Length Machine

- Combined Drawing, Straightening, Cutting and Polishing Machine

- Wire Shaving Machine

- Continuous Annealing furnaces

- Vacuum annealing Furnaces

- Schumag Drawing machines, Peeling machines, Centerless grinding machines

Hexagonal bolts, Hexagonal socket, Head cap screws, Cheese Head screws, Countersunk screws, Locking washers, and Plates, Wire locking screws and Nuts, Studs, Specialised and Custom made fasteners, Lock nuts, Locking plates and Split bushes, etc.

Vacuum Investment Castings facility enables MIDHANI to manufacture & supply near net shape Investment Castings to fulfill the need of strategic sector of India. MIDHANI’s Vacuum Investment Castings Plant is equipped with the followings facilities:

300 Kg VAR – Skull Melting Furnace

120 Kg VAR – Skull Melting Furnace

60Kg Vacuum Induction Precision Casting Furnace

In House Die Design & Development

Mechanized Shell Manufacturing Facility

Casting Simulation Software (ProCAST)

MIDHANI is manufacturing & supplying investment castings in the following Grades:

Titanium Alloys

Iron Base Super Alloy

Nickel Base Super Alloys

Cobalt base Super Alloys

High Entropy Alloys

Special Steel Alloys

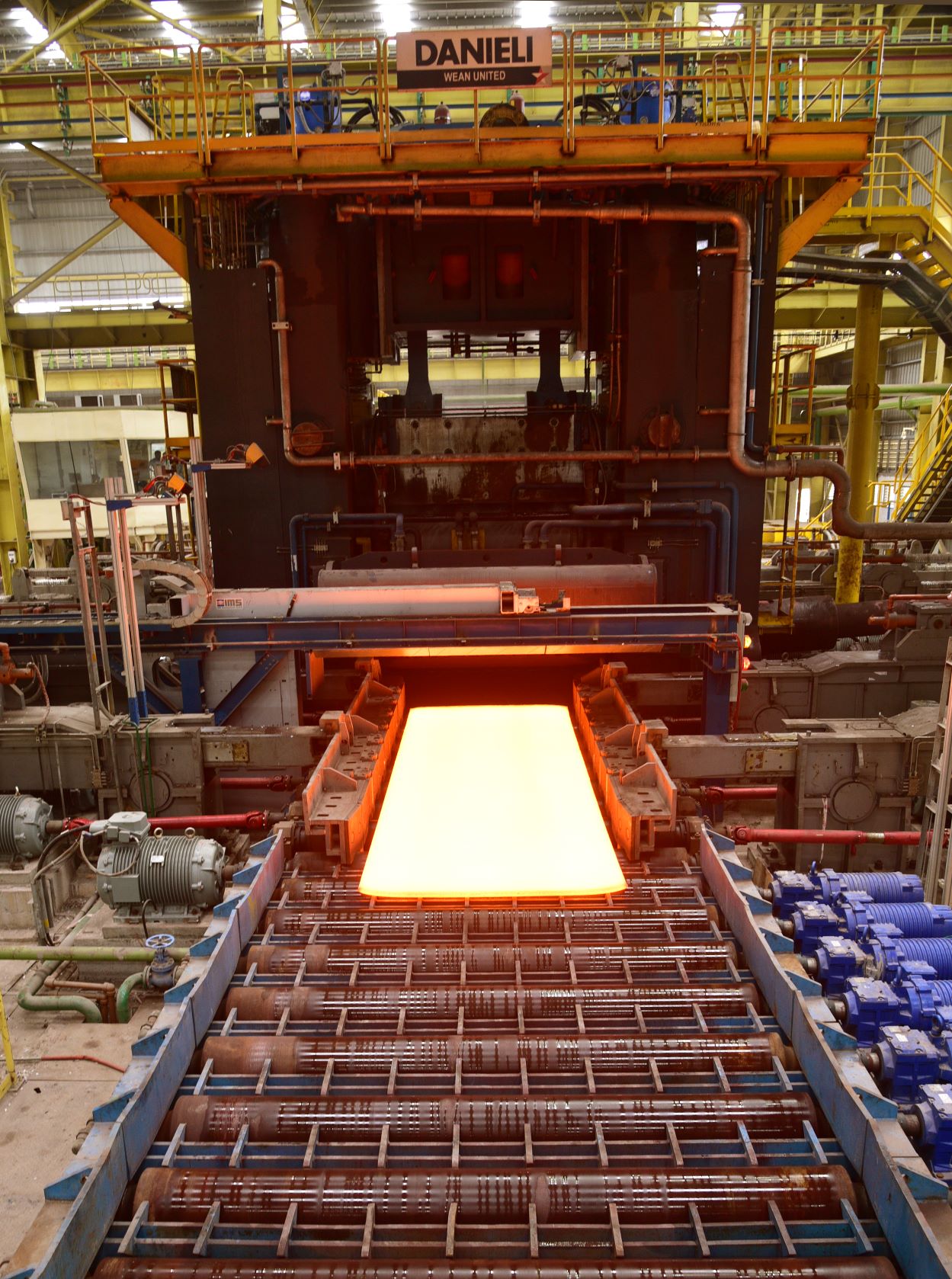

MIDHANI have setup Wide Plate Mill (WPM) facility in Hyderabad. This facility is setup with state-of-the-art Single Stand Reversing stand with a massive capacity of 6000 metric tons of roll separating force, with all necessary ancillary processes in Levelling, shearing, distortion free quench-hardening, tempering, and sizing, etc. This facility has all the innovative features that fulfil the requirements for high metallurgical quality, tight dimensional tolerances, enhanced mechanical properties and improved surface quality.

This facility is established with the following major equipment along with all auxiliary and material handling facilities:

• Re-heating furnace

• 4-Hi Single Stand Reversing Hot Rolling Mill

• Dividing Crop shear

• Hot/Cold Leveller

• Cooling bed

• Heat treatment Furnace

• Roller Pressure quench

• Tempering Furnace

This facility will ensure self-reliance in production of extra wide plates of Ultra high strength steels, Superalloys, Stainless Steels, Special Steels, Armour Steels, Titanium and Titanium Alloys in widths upto 3000mm and thickness down to 5 mm. The finished product dimensions are as follows:

| Dimensions | Finished plates [mm] |

|---|---|

| Thickness | 5 – 50 |

| Width (<6mm) | 1000 – 3000 (≤2000) |

| Length (<6mm)) | 5000-15000 (≤2000) |

Spring plant with a capacity of 60,000 Springs per year has been set up to manufacture Springs indigenously.

Hot Spring coiling machine for Production of Helical Springs for manufacturing and supply of

Helical Compression Springs for Railway Wagons, Coaches, Locomotives, etc.

In Machining Centre, various machining operations like cutting, Turning, Milling, Drilling and Polishing are taking place.

The facilities are as follows:

I.LATHE MACHINES:

1.Vertical Turning Lathe Machine capacity 2000mm , Height 1000mm – 3NO

2. HDL70/4.0 Lathe Machine Capacity 1400mm Swing Over diameter & 1600 mm Swing over Gap bed, 4.0 meters Length. – 1NO

3. L45/8.0 Lathe Machine Capacity 900mm Swing over diameter, 8.0meters length – 1NO

4. L45/3.0 Lathe Machine Capacity 900mm Swing over diameter, 3.0meters length – 11NO

5. NH26/3.0 lathe Machine Capacity 520mm swing over diameter, 3.0meteres length – 2NO

6. NH26/2.0 lathe Machine Capacity 520mm swing over diameter, 2.0meters length – 1NO

7. NH22/2.0 Lathe Machine Capacity 440mm swing over diameter, 2.0meters length – 2NO

8. NH 22/3.0 Lathe Machine Capacity 440mm swing over diameter, 3.0meters length – 1NO

9. NH 26/1.5 Lathe Machine Capacity 520mm swing over diameter, 1.5metres length – 2NO

10. Roll Turning Lathe Machine is used for making the grooves for the HOT ROLLING MILLS – 1NO

II.MILLING MACHINES:

1.Wadkin Milling Machine capacity 900mmx1200mm Table – 1NO

2.UF3.5 Milling Machine capacity 900mmx900mm Table and universal Milling Head – 1NO

3.FN3H Milling Machine capacity 400mmx900mm Table – 3NO

4.HF 3.5 Milling Machine capacity 400mmx900mm Table – 2NO

5.VF2.5 Milling Machine capacity 200mm x 500mm Table – 1NO

6.Kirloskar Milling Machine capacity 1000mm X2000mm Table – 1NO

7.Plano Milling Machine capacity 1000mm X2000mm Table – 1 NO

III.DRILLING MACHINES:

1. Radial Drilling Machine RM-65 capacity drilling 55mm – 2NO

IV.BELT GRINDING MACHINE:

1. Belt grinding machine capacity 9000mmx3000mm Table for sheets polishing – 2NO

2. Belt grinding machine capacity 3000mmx2000mm Table for sheets polishing – 2NO

V.CUTTING MACHINES:

1.Indotech Cutting Machine Capacity: 450mmx450mm rounds 460square – 2NO

2.Indtools Cutting Machine Capacity: 460mmx460mm round 480mm square – 1NO

VI.BAR TURNING MACHINE:

1.Bar Turning Machine capacity Min dia 12mm, max dia 35mm – 1NO

VII.CENTRELESS GRINDING MACHINE:

1. Centreless Grinding Machine(GCL140) capacity Min dia 10mm, Max dia 45mm – 1NO